In conclusion, the walking foot zigzag sewing machine is a valuable investment for anyone serious about sewing. Its ability to accommodate a wide range of fabrics, coupled with the freedom to create intricate zigzag stitches, makes it an indispensable tool in the sewing arsenal. Whether you are crafting a cozy quilt, a fashion-forward garment, or home décor items, this machine enhances your sewing experience, bringing both quality and creativity into every project. As technology continues to evolve, the walking foot zigzag sewing machine remains a timeless companion for seamstresses who value precision, versatility, and artistry.

Home

Home

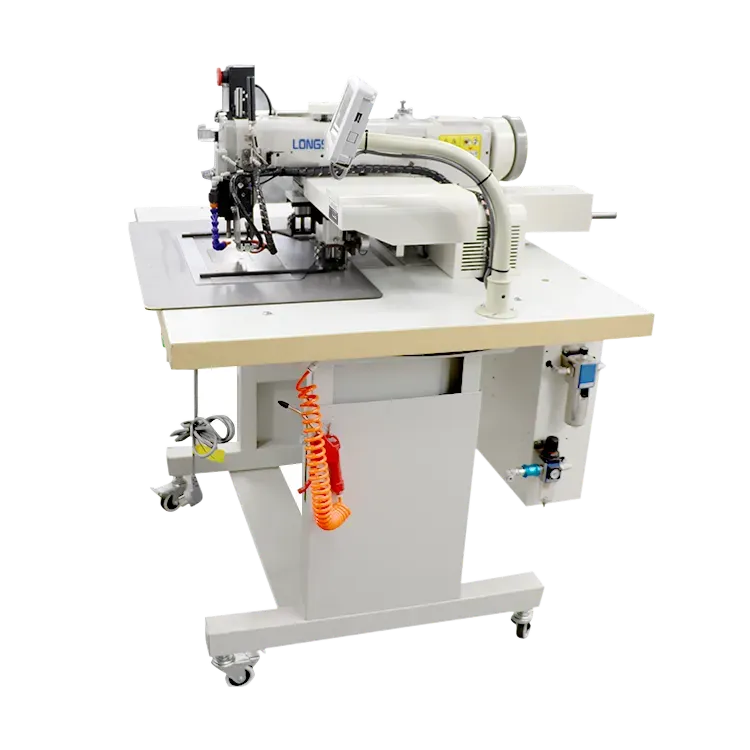

Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models

Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models Machines with advanced features such as automatic thread trimming, programmable stitch patterns, and digital displays will typically cost more than basic models